Drott 50, 50D, D Series Crawler Excavator Service Manual S406236M2 English

Brand: CASE Construction / Drott

Product Range: Crawler Excavator

Publication Type: Service Manual

Equipment Model: 50, 50D, D Series Excavator

Serial Number: -

Publication Number: S406236M2

Issued: Printed in U.S.A. (Reprinted)

Language: English

Pages: 217

File Format: PDF Document

Additional Information: All components and systems are included, with the exception of the engine. For Engine Repair, See the Engine Service Manual.

Introduction

This manual provides instructions for maintenance and service of the DROTT 50 series "D" Crawler. All components and systems are included, with the exception of the engine which is covered in the engine manufacturer's manual supplied with each machine.

The manual is divided into six sections, preceded by a general section on safety, machine description and specifications.

A separate section entitled "Scheduled Preventive Maintenance" is provided to cover all components which require periodic maintenance. Refer to this section whenever performing normal maintenance. It includes a Maintenance Schedule, Component Capacities, Hydraulic System Operating Pressures, Maintenance Chart and Maintenance Details.

The Service section is divided into three general areas - Mechanical, Electrical and Hydraulic. Included in the Service section is general descriptive and operational information to provide a basic understanding of each system and its components. All disassembly and repair information is contained in the last section of the manual and arranged in the general sequence established in the service section, i.e. Mechanical, Electrical and Hydraulic.

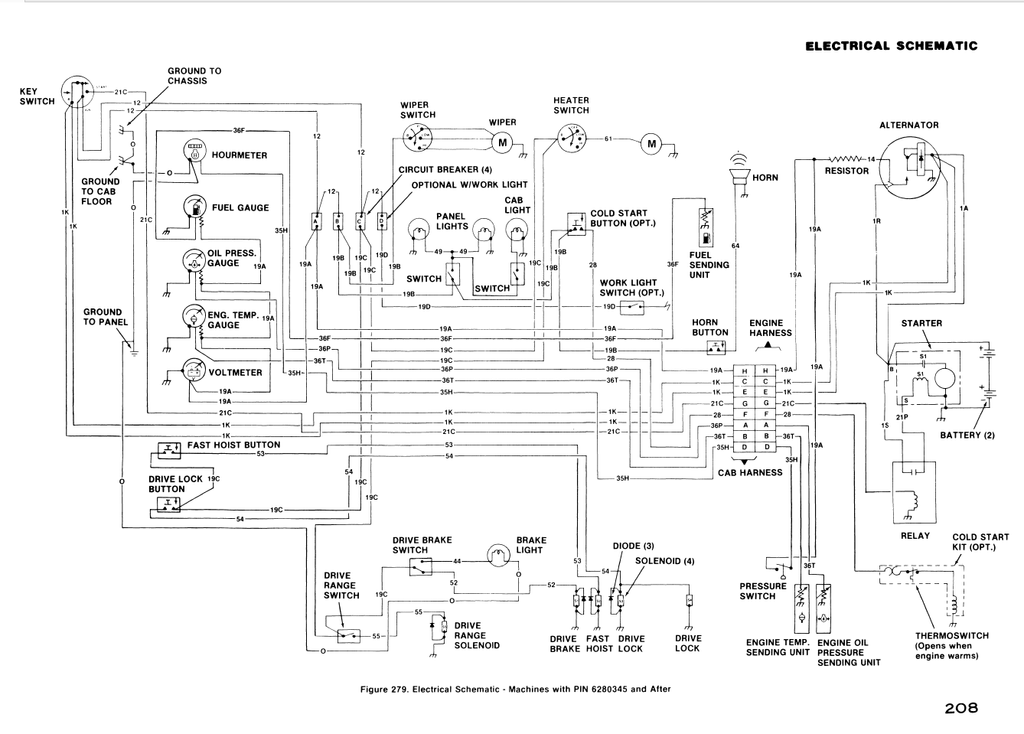

Troubleshooting charts for all the systems are contained in a separate section (See Section 5). Torque Charts and Schematic Drawings of the Electrical and Hydraulic systems are located in back of this manual for easy reference when troubleshooting the machine.

Table of Contents

GENERAL

Safety Precautions

Introduction

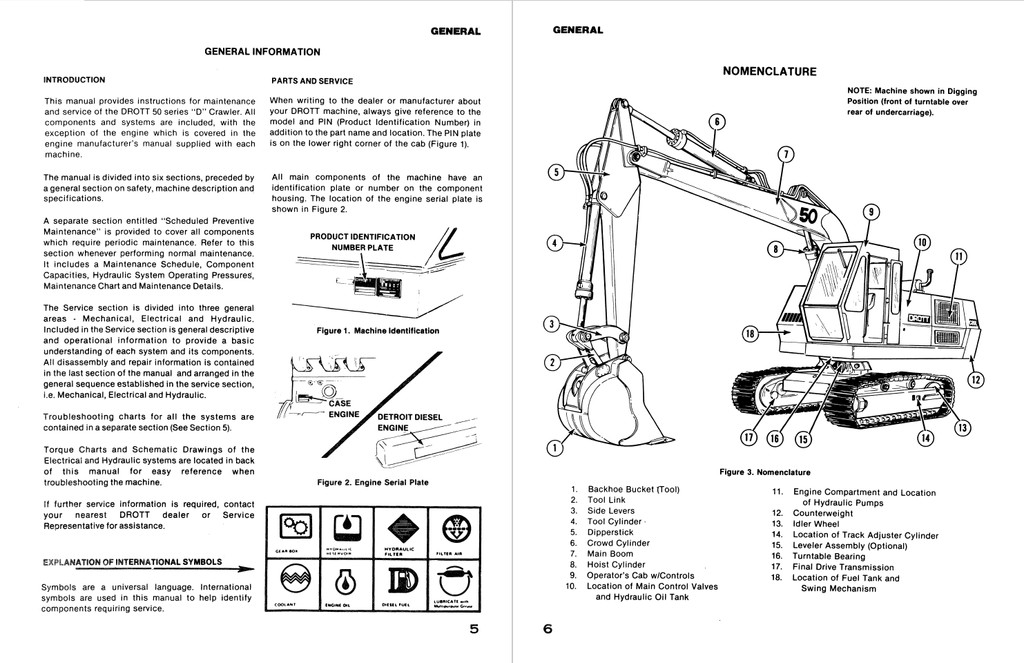

Nomenclature and General Description

Specifications

SECTION 1 - SCHEDULED PREVENTIVE MAINTENANCE

Introduction

Hydraulic Oil Recommendations

Hydraulic System Operating Pressures

Component Capacities

Rated Pump Output

Maintenance Chart

Illustrated Listing of Grease Fittings

Itemized Maintenance Instructions

SECTION 2 - MECHANICAL SYSTEM

Undercarriage

Engine and Related Parts

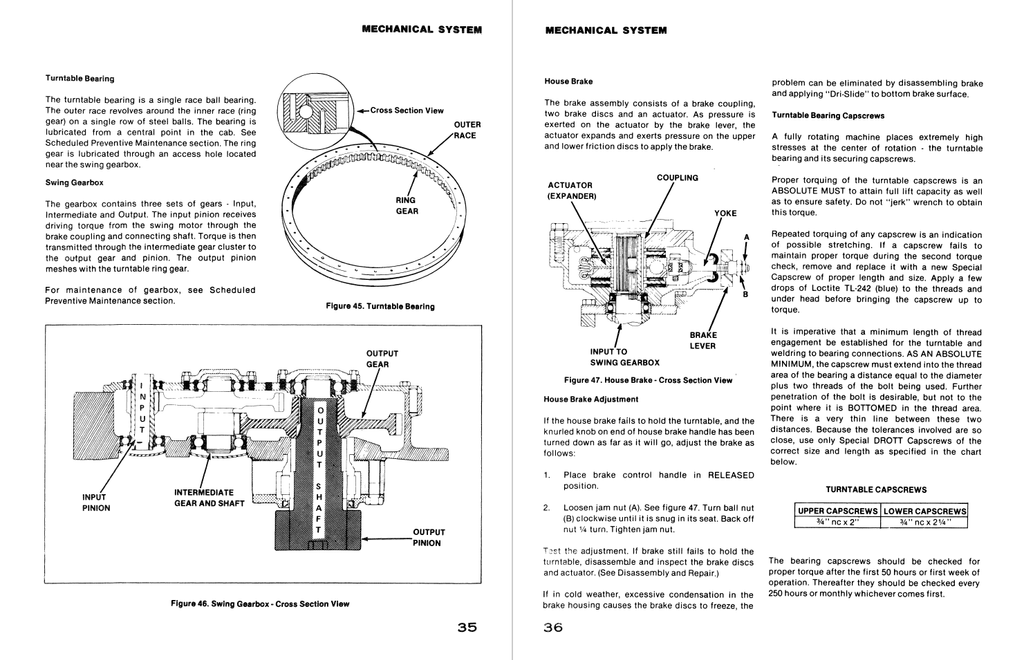

Turntable Swing

Boom and Attachments

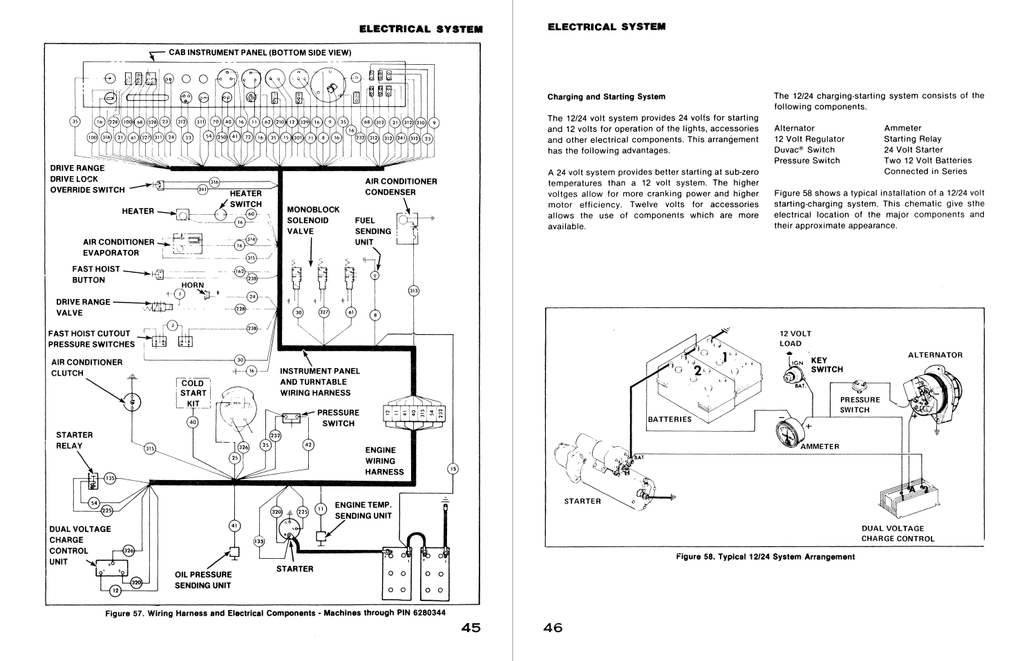

SECTION 3 - ELECTRICAL SYSTEM

Introduction

12/24 Volt System (Machines through PIN 6280344)

24 Volt System (Machines with PIN 6280345 and After)

Control Circuits

Lights and Instrumentation Circuits

SECTION 4 - HYDRAULIC SYSTEM (For pressures, see page 10)

Introduction

System Maintenance

Main Hydraulic System

General Description

Hydraulic Pump

Main Control Valves

Port Relief Valves

Explanation of "Summated" System

Power Sensing Valve

Main Relief Valves

Track Drive Hydraulics

Drive Motor Circuits

Digging Brake Release Circuit

Solenoid Control Valve

Hydraulic Swivel

Swing Hydraulics

Hoist Hydraulics

Hydraulic Circuits to Crowd Cylinder and Tool Cylinder

Leveler Hydraulics

Pilot Control System

SECTION 5 - TROUBLESHOOTING

Introduction

Engine

Undercarriage

Electrical System

Pilot Control System

Main Hydraulic System

Track Drive System

Swing System

Cylinder Circuits

Main Pump

Main Control Valves

Relief Valves

SECTION 6 - DISASSEMBLY AND REPAIR

General Cleaning Instructions

leveler Assembly

Track Chain

Track Adjustment Cylinder

Track Rollers

Idler Wheel

Digging Brake

Final Drive Transmission

Engine and Pump Drive

House Brake

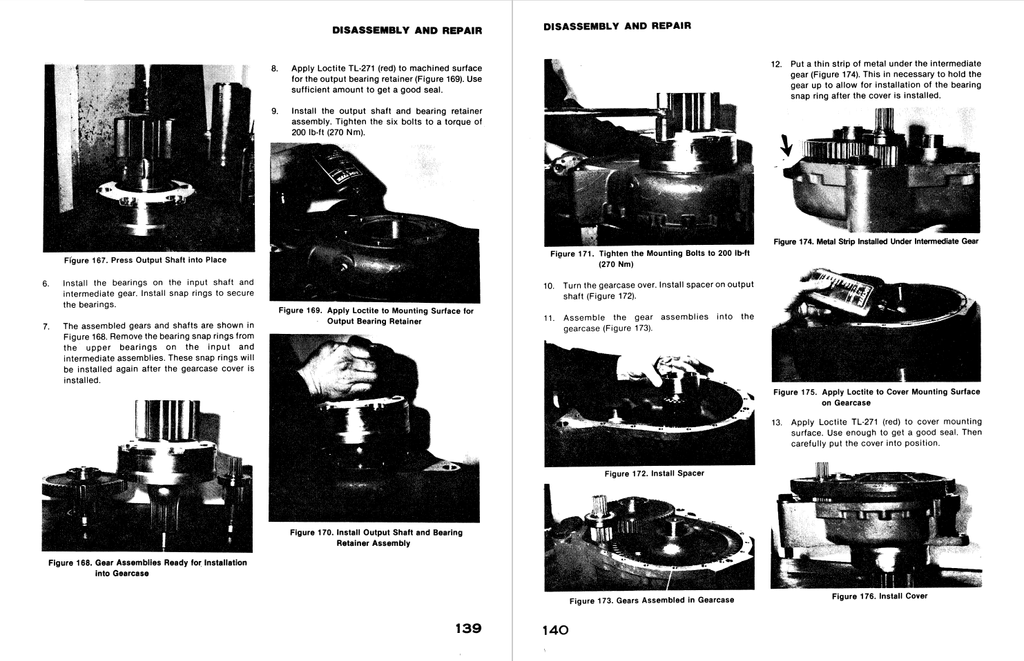

Swing Gearbox

Turntable Bearing Replacement

Boom

Wiring Harness Replacement

Main Hydraulic Pump

Pilot Hydraulic Pump

Main Control Valves

Power Sensing Valve

Pilot Control (Modulator) Valves

Track Drive Motor

Swing Motor

Swing Cushion Valve

Leveler Lock Valve

Hydraulic Swivel

Hydraulic Cylinders

Hydraulic Oil Tank

Solenoid Control Valve

TORQUE CHARTS AND SCHEMATICS