Drott 35B, 40B, 50B B Series Crawler Excavator Service Manual S406173M2 English

Brand: CASE Construction / Drott

Product Range: Crawler Excavator

Publication Type: Service Manual

Equipment Model: 35B, 40B, 50B B Series Crawler Excavator

Serial Number: -

Publication Number: S406173M2

Issued: Printed in U.S.A. (Reprinted)

Language: English

Pages: 234

File Format: PDF Document

Additional Information: Procedures for maintaining and servicing all components and systems are provided with the exception of the engine. For Engine Repair, See the Engine Service Manual.

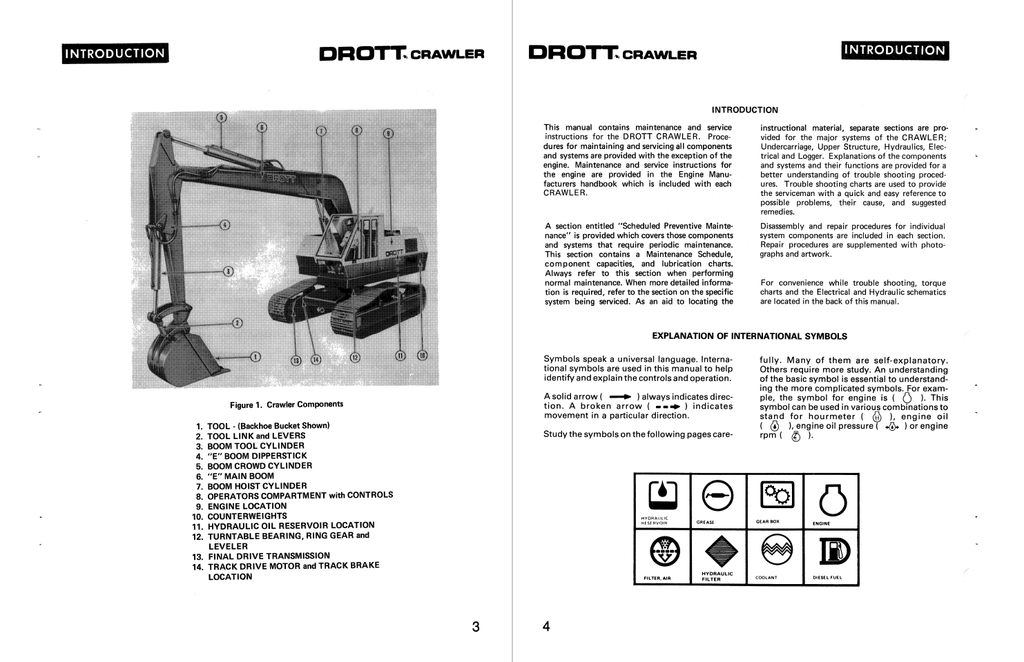

Introduction

This manual contains maintenance and service instructions for the DROTT CRAWLER. Procedures for maintaining and servicing all components and systems are provided with the exception of the engine. Maintenance and service instructions for the engine are provided in the Engine Manufacturers handbook which is included with each CRAWLER.

A section entitled "Scheduled Preventive Maintenance" is provided which covers those components and systems that require periodic maintenance. This section contains a Maintenance Schedule, component capacities, and lubrication charts. Always refer to this section when performing normal maintenance. When more detailed information is required, refer to the section on the specific system being serviced. As an aid to locating the instructional material, separate sections are provided for the major systems of the CRAWLER; Undercarriage, Upper Structure, Hydraulics, Electrical and Logger. Explanations of the components and systems and their functions are provided for a better understanding of troubleshooting procedures. Troubleshooting charts are used to provide the serviceman with a quick and easy reference to possible problems, their cause, and suggested remedies.

Disassembly and repair procedures for individual system components are included in each section. Repair procedures are supplemented with photographs and artwork.

For convenience while troubleshooting, torque charts and the Electrical and Hydraulic schematics are located in the back of this manual.

Table of Contents

GENERAL

Table of Contents

Safety Precautions

Nomenclature

Introduction

Safety Symbols

Directional Reference

Parts and Service

SCHEDULED MAINTENANCE

Introduction

Cleaning Soundproofing Insulation

Spark Arrestors

Lubricant and Fluid Recommendations

Hydraulic Oil Recommendations

Component Lubricants and Fluid Specifications

Hydraulic System Operating Pressures

Preventive Maintenance Schedule

Lubrication and Service Chart

Pictorial Listing of Grease Fitting Locations

Itemized Maintenance Instructions

Hydraulic Oil Filters

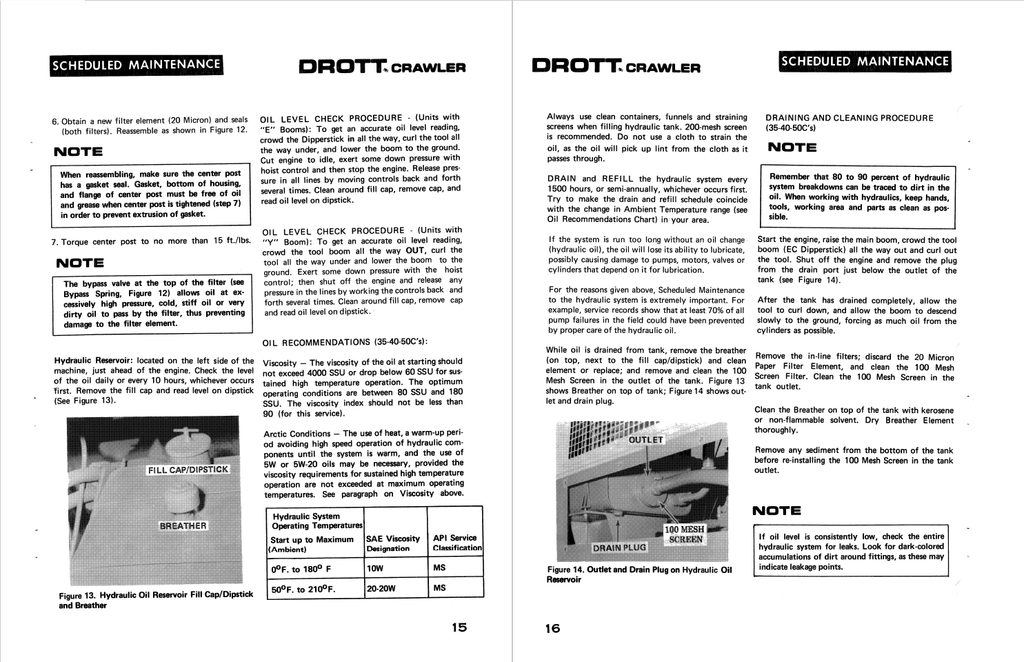

Hydraulic Reservoir

Hydraulic Oil Filter Screen (in-tank)

Swing Reduction Gearbox

Final Drive Transmissions

Turntable Open Gear

Engine

Engine Coolant

Oil Cooler

Batteries

Air Cleaner

Fuel Tank

CRAWLER UNDERCARRIAGE

General Description

Frames

Track Shoes

Track Rollers

Track Drive Motors

Track Drive Brake

Adjustment

Removal

Disassembly

Inspection and Repair

Mounting Track Brake to Final Drive Transmission

Final Drive Transmission

Trouble Shooting

Removal

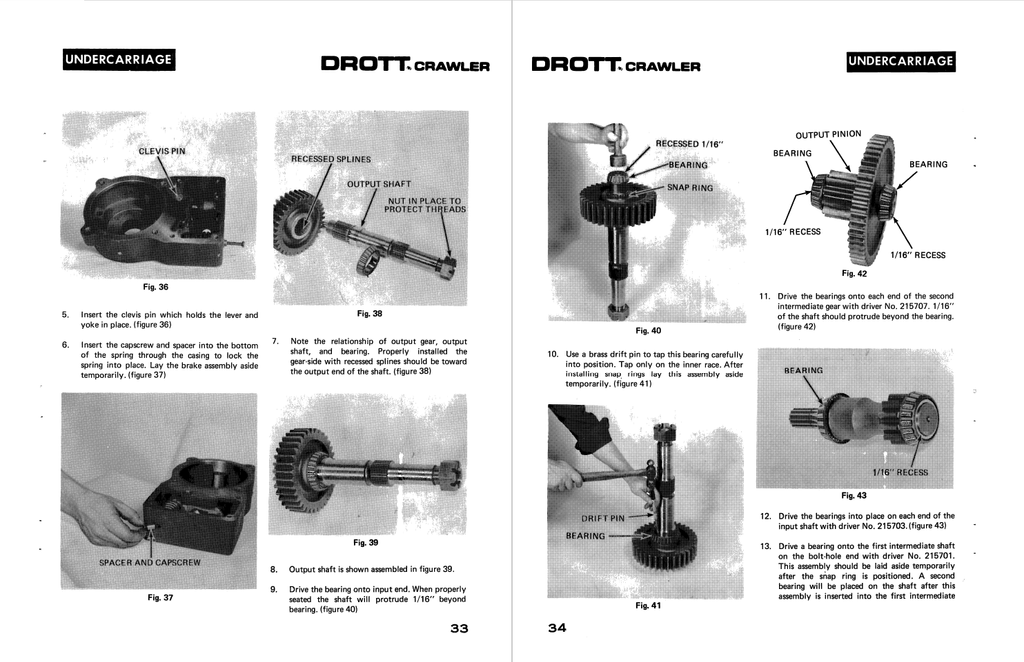

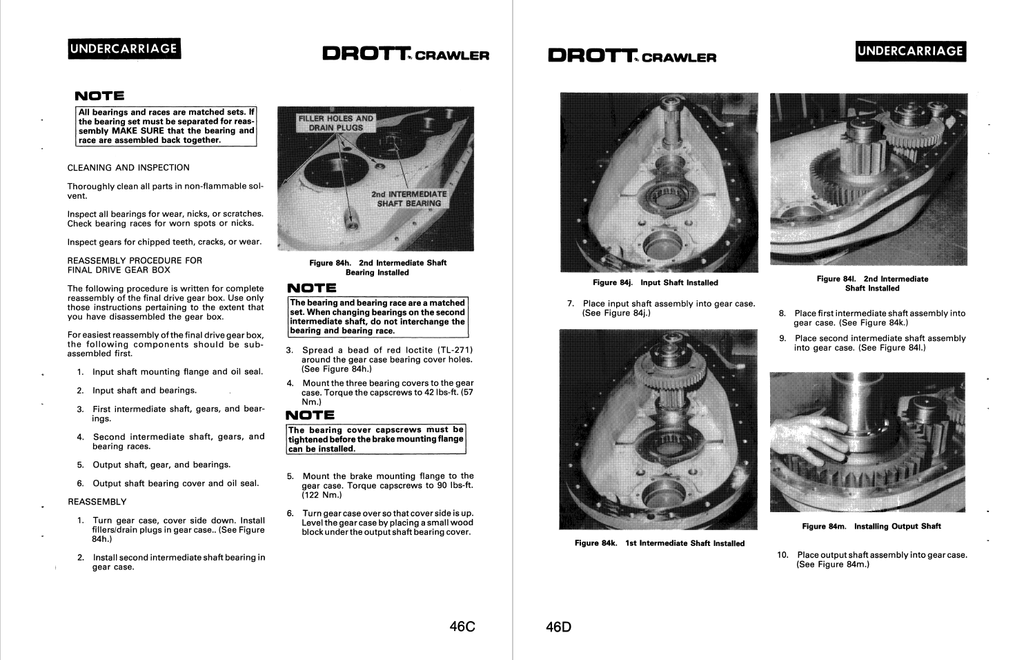

Disassembly, Inspection and Re-assembly

Disassembly, Inspection and Re-assembly (40LC only)

Scheduled Maintenance (40LC only)

Track Adjustment Cylinder

Idler Wheel

Carbody and Carbody Leveler

Carbody Leveler Cylinder

Trouble Shooting - Tracks

UPPERSTRUCTURE

Replacing the Turntable Bearing

Removing the Upper

Checking Bearing Mounting Surface

Installing Bearing to Upper

Installing Upper to Lower

Torquing Procedure

Turntable Bearing Noise

Replacing Turntable on Machine without

Machined Bearing Mounting Surface

Swing Mechanism

Brake

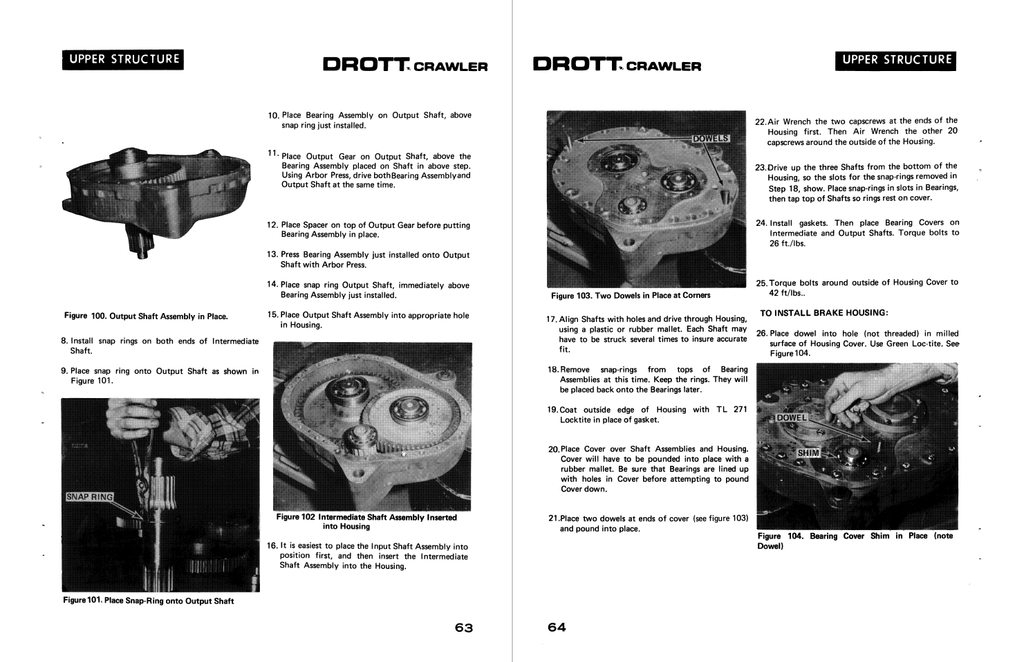

Reduction Gearbox (2 piece output shaft)

Reduction Gearbox (1 piece output shaft)

Motor

Reduction Gearbox

Shimming the Gearbox

Disassembly and Repair

Installation

HYDRAULIC SYSTEM AND COMPONENTS

Introduction to Hydraulics

Troubleshooting

Flushing Procedure

Basic System Flow Diagrams

Main Tandem Pump

Description

Checking Gallonage Output

Removal

Disassembly, Inspection and Reassembly for:

Main Pump (used on 35 Crawlers)

Main Pump (used on 40 and 50 Crawlers)

Swing Motors

Installation of Pump Drive

Pump Breakin Procedure

Track Drive Motor (40BLC and 50LC)

Removal and Repair

Clam Rotary Actuator (270°)

Hydraulic Swivel

Valve Banks

Description

Removal

Power Beyond Plug

Deviation of Valve Body

Series Spool - Seal Replacement

Parallel Spool - Seal Replacement

Main Relief Valve

Relief Cartridge in Leveler Valve

Disassembly of Main Relief

Port Relief Valve

Swing Cross-Over Relief Valve

Track Brake Valve

Check Valves

Flow Regulators

Hydraulic Cylinders

Trouble Shooting Guides

Oil Flow Diagrams for:

Tool Cylinder Circuit

Crowd Cylinder Circuit

Hoist Cylinder Circuit

Leveler Cylinder Circuit

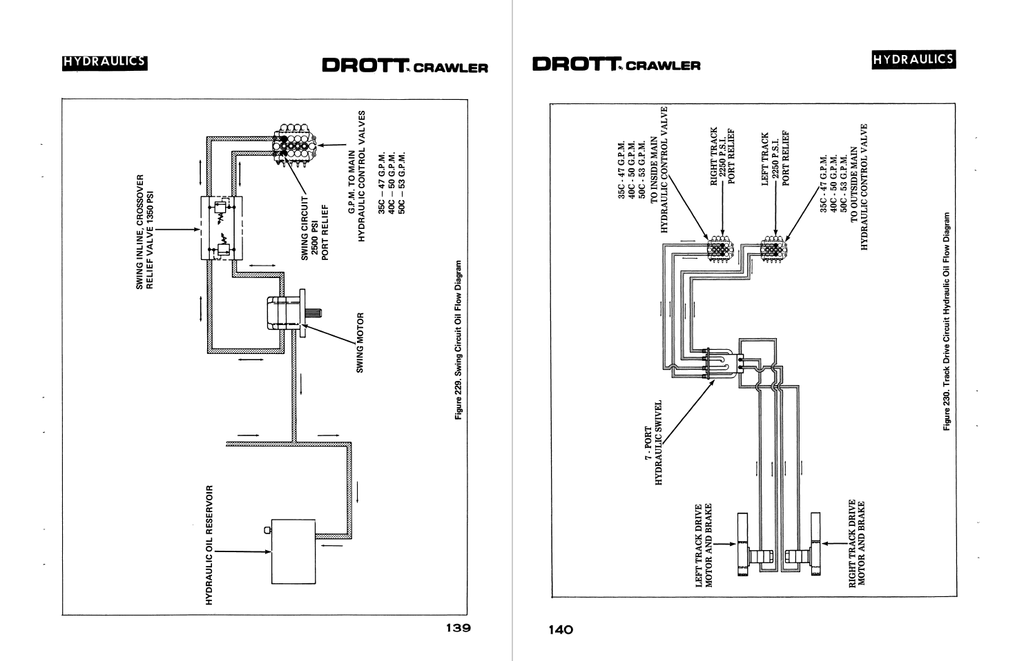

Swing Circuit

Track Drive Circuit

Track Brake and Drain Circuit

Feller/Buncher Circuit

Feller/Buncher Collector Circuit

ELECTRICAL

General Description

Battery Care

General Trouble Shooting

Trouble Shooting Guide

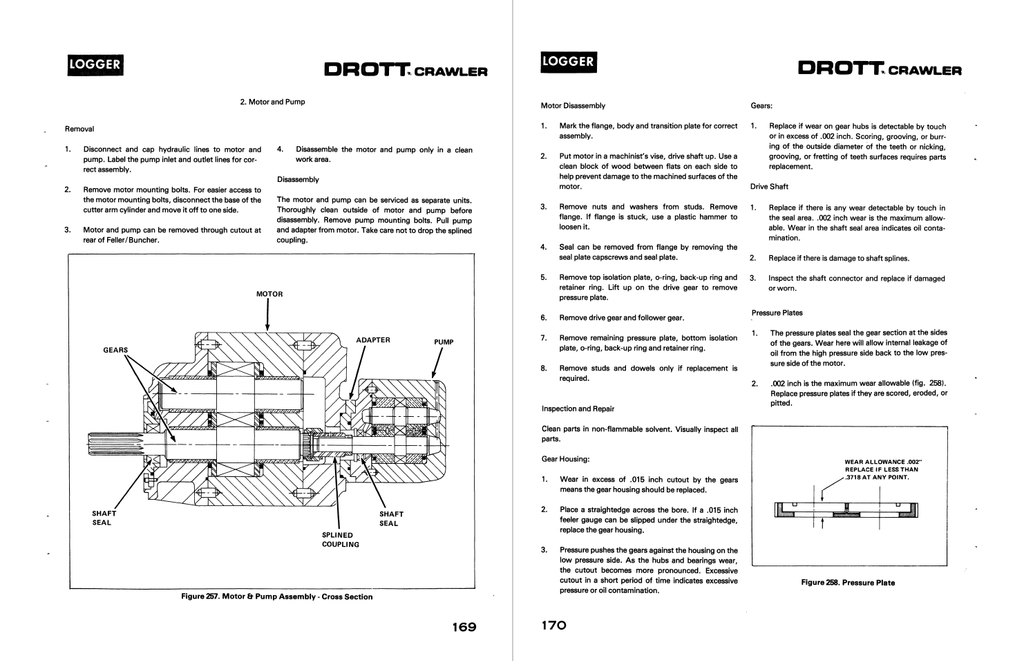

LOGGER

General Description

Feller/Buncher Maintenance

Feller/Buncher Collector

Rotary Cutter

MISCELLANEOUS

Torque Charts

Hydraulic Schematic

Electrical Schematic